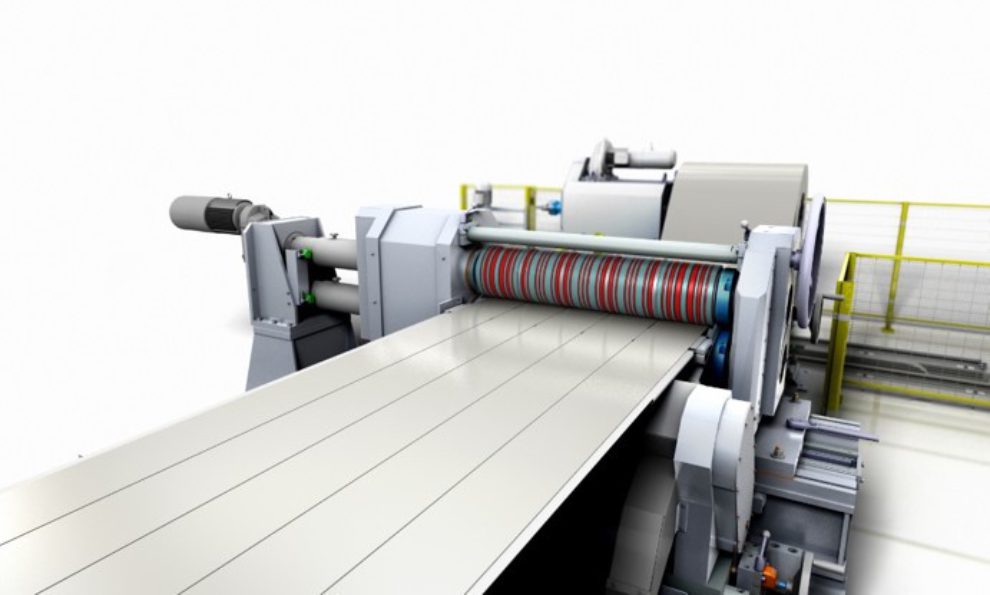

Slitting line for narrow coils

Soenen developed a narrow coil slitting line, with a very high precision of the slitting head.

Client

Euro-Mit Staal BV in Vlissingen, The Netherlands, with Mitsui & Co as main shareholder, is specialized in slitting thin gauge plate, mainly electrical steel for the transformer industry.

Challenge

To increase their production capacity Euro-Mit Staal BV was looking for a slitting line for narrow coils. The required minimum coil width after slitting was 10 mm (0.4 inches). The thickness of the electrical steel ranged between 0.18 mm and 0.35 mm (0.007 and 0.014 inches). For other thin gauge plate, the thickness can vary from 0.20 mm up to 0.50 mm (0.008 up to 0.02 inches). Compatibility with an existing tool system was a requirement.

Solution

Soenen developed a narrow coil slitting line, meeting the specific requirements of the customer. The line is characterized by a very high precision of the slitting head. This gives a very high slitting quality. Even thinner gauges of 0.10 mm (0.004 inches) can be slit. To cut the edge trimming scrap a new type of scrap chopper was designed. The carbide chopper knives have 4 cutting edges. An uncoiler and recoiler allow inner diameters of 406 mm and 508 mm (16 in and 20 inches). Recoiling is done either directly on the mandrel or on a cardboard core. The maximum speed of the line is 190 m/min (+-600 ft/min). At the end of the coil, the line is decelerated automatically. The line allows to rewind coils to obtain the required strip length or weight on the new coil. Therefore the line is equipped with a length measuring system and a user friendly manual shear to cross cut the coil. The line is controlled by user friendly software that gives a lot of information on the status of the line.

Why Valtech Group?

This tailor-made project is in line with the philosophy of the Valtech Group where the different machine manufacturers supply projects meeting the specific requirements of the customer. Moreover a number of components of the slitting line were supplied by other companies within the Valtech Group, such as Haeck for turning and milling work and Allhydro for hydraulic components.